Comparing Polymer Materials Made Easy: Guide Your Clients with Fabrex CRM

For many customers, choosing the right material is the most confusing part of a 3D printing project. Do they need strength? Flexibility? Heat resistance? The wrong choice can mean part failure—or a lost opportunity for you. Fabrex CRM turns your quoting process into a consultative, value-added experience. It helps you educate customers in real time, giving them the confidence to approve quotes faster and come back for more.

How Fabrex CRM Supports Smart Material Guidance

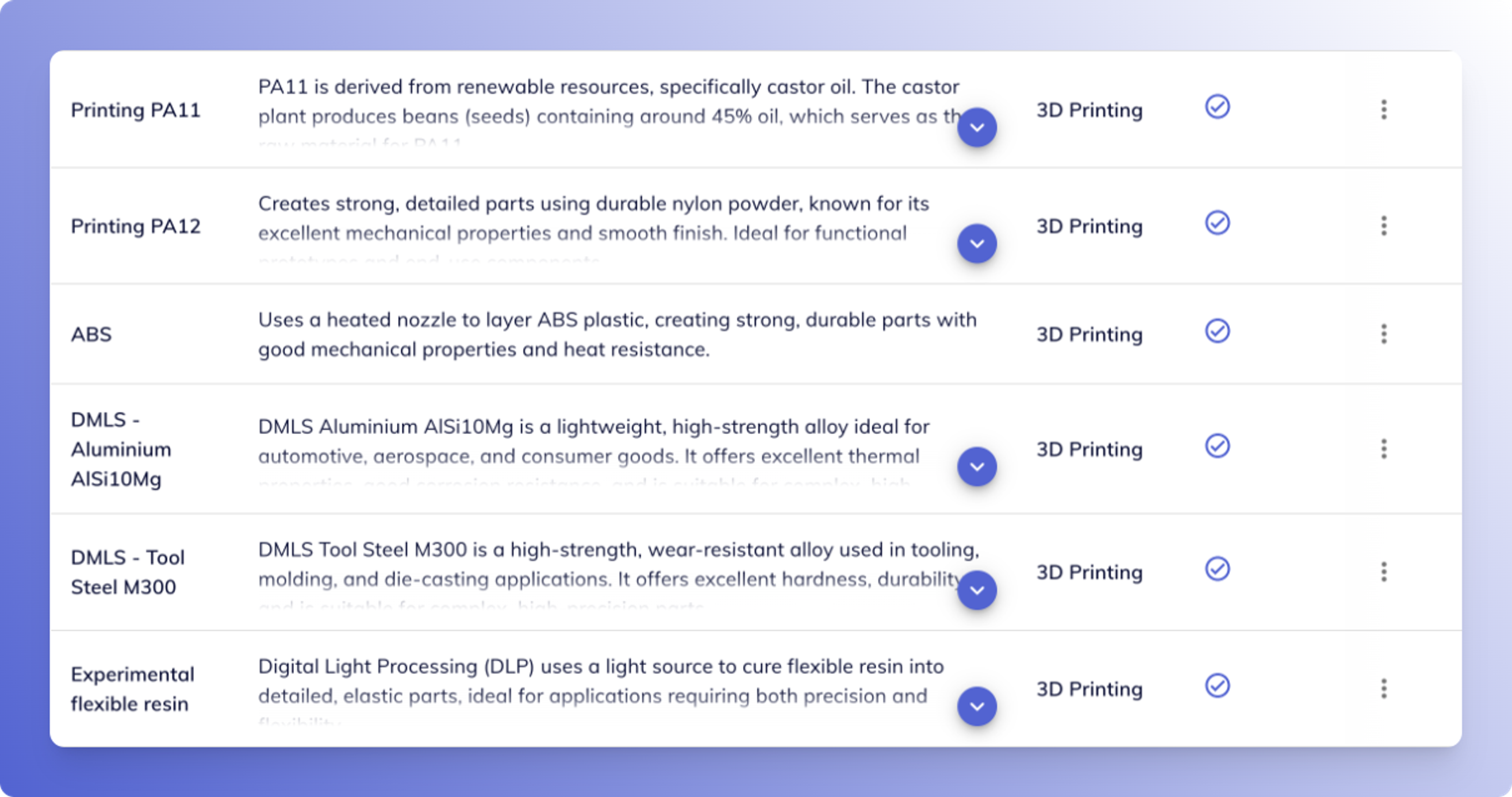

Pre-loaded Material Profiles

Build a library of printable materials (like PLA, PETG, ABS, Nylon) with attributes, certifications, pricing tiers, and printable specs.

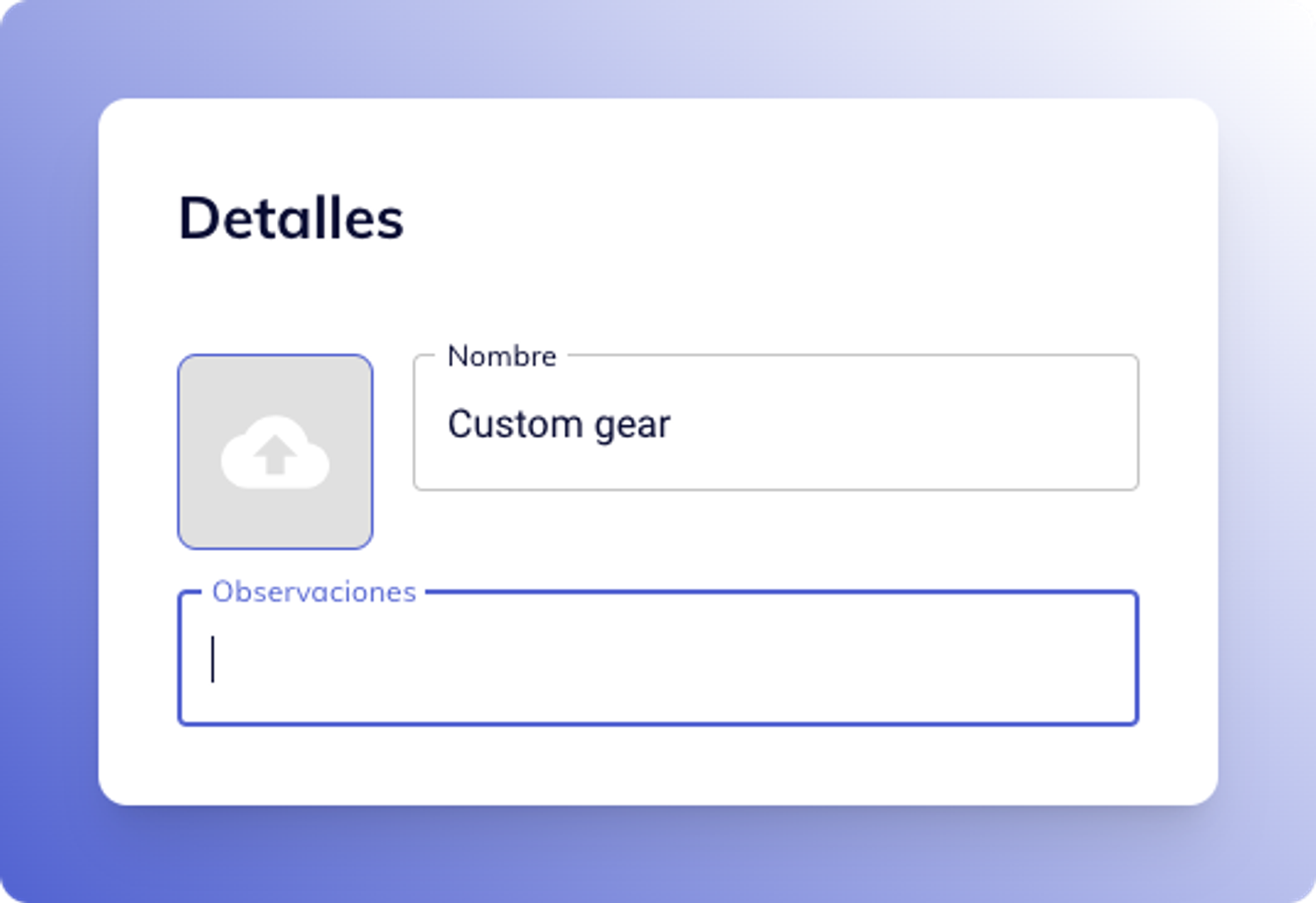

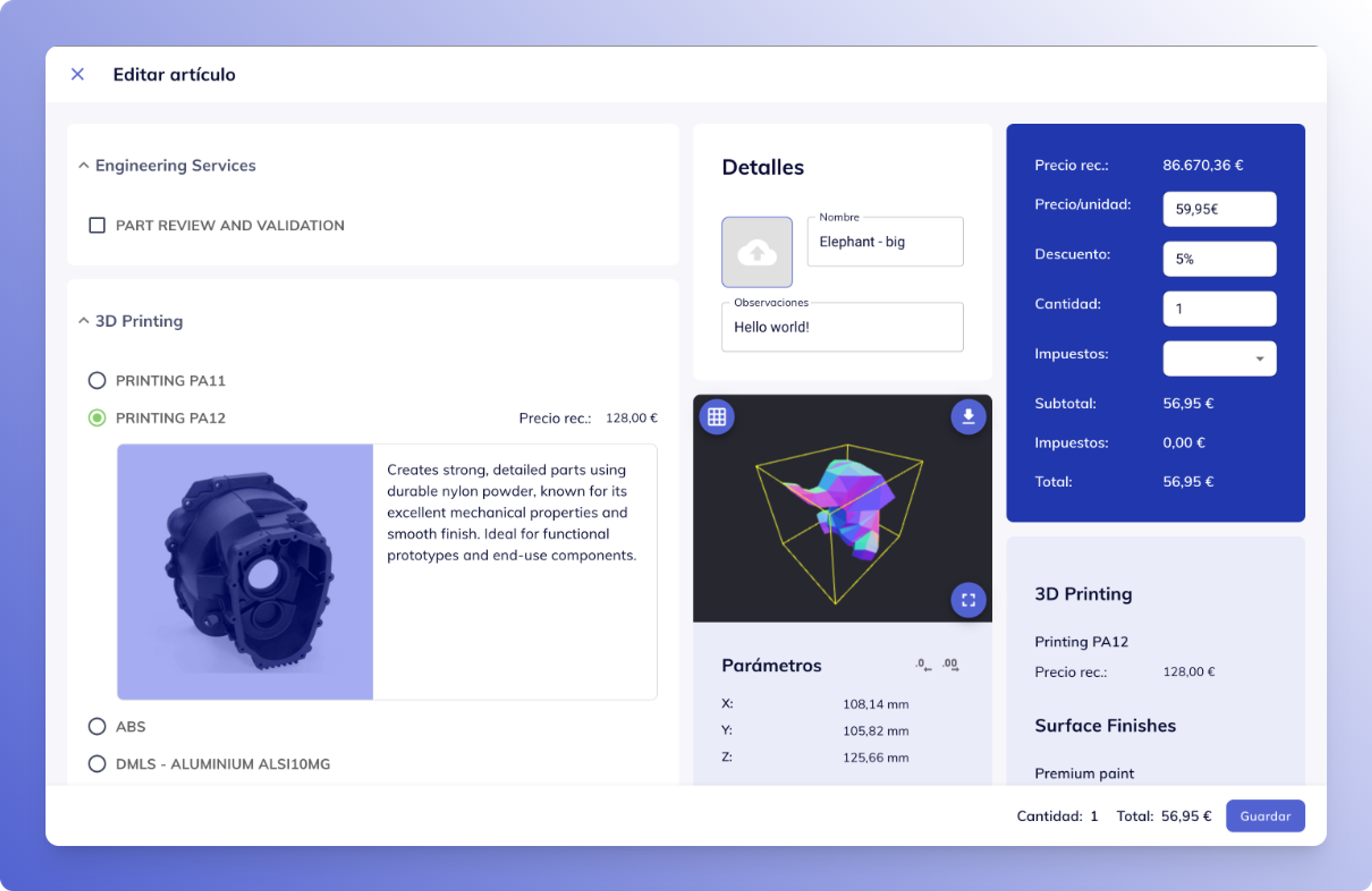

Attach Comparisons to Quotes

Send quotes with embedded material guidance—clients can see what you recommend and why.

CRM Notes and Templates

Use internal templates to guide your sales team on how to recommend materials by application type.

Core Features That Simplify the Decision

Attribute Tags for Each Material

Easily filter by properties like stiffness, temperature resistance, printability, and price.

Application Match Suggestions

Label materials by common use cases (e.g. “great for mechanical parts” or “ideal for visual prototypes”).

Visual Comparison Tools

Share charts or visuals right in the quote email or client portal.

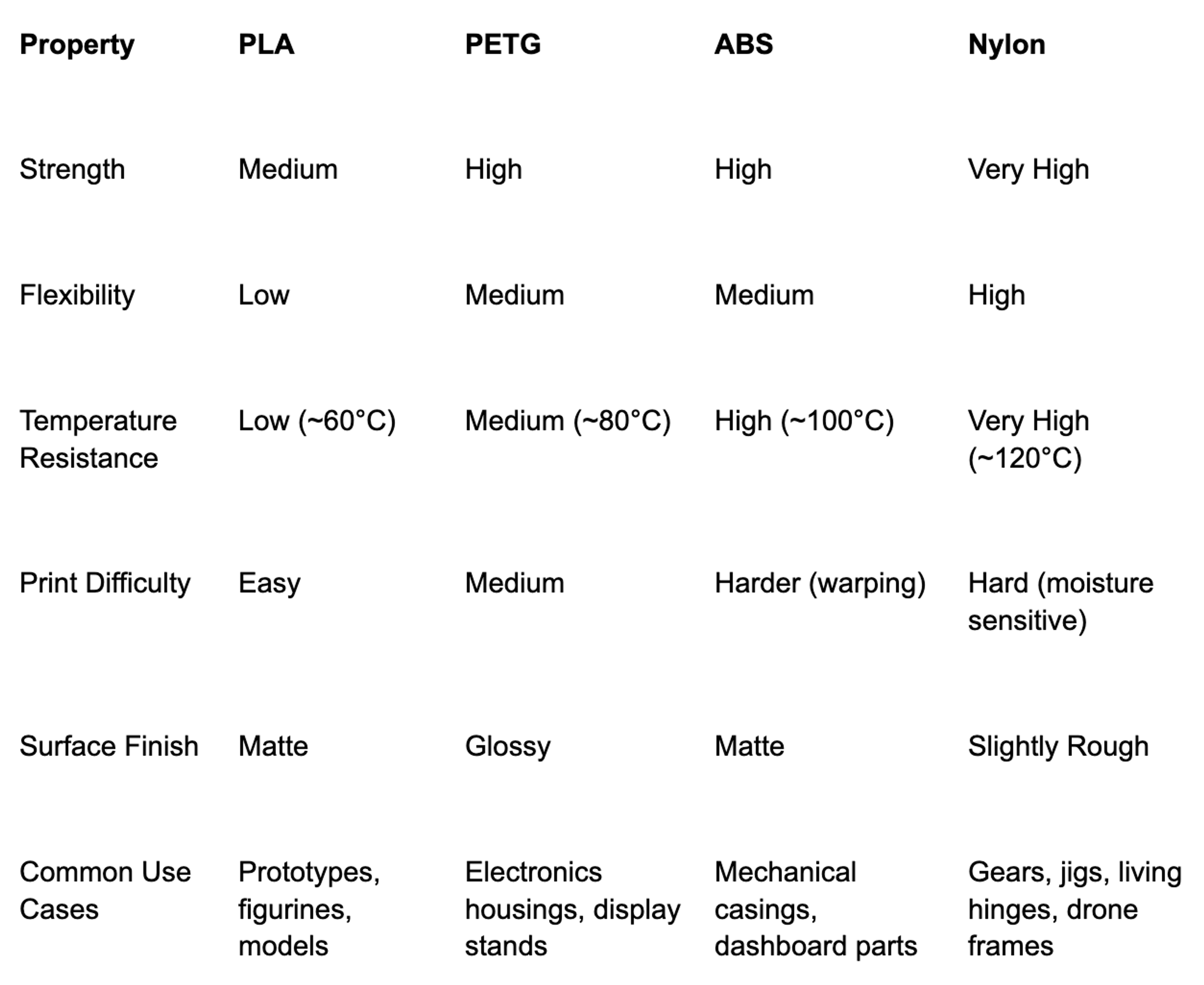

Comparison Table: Common 3D Printing Materials

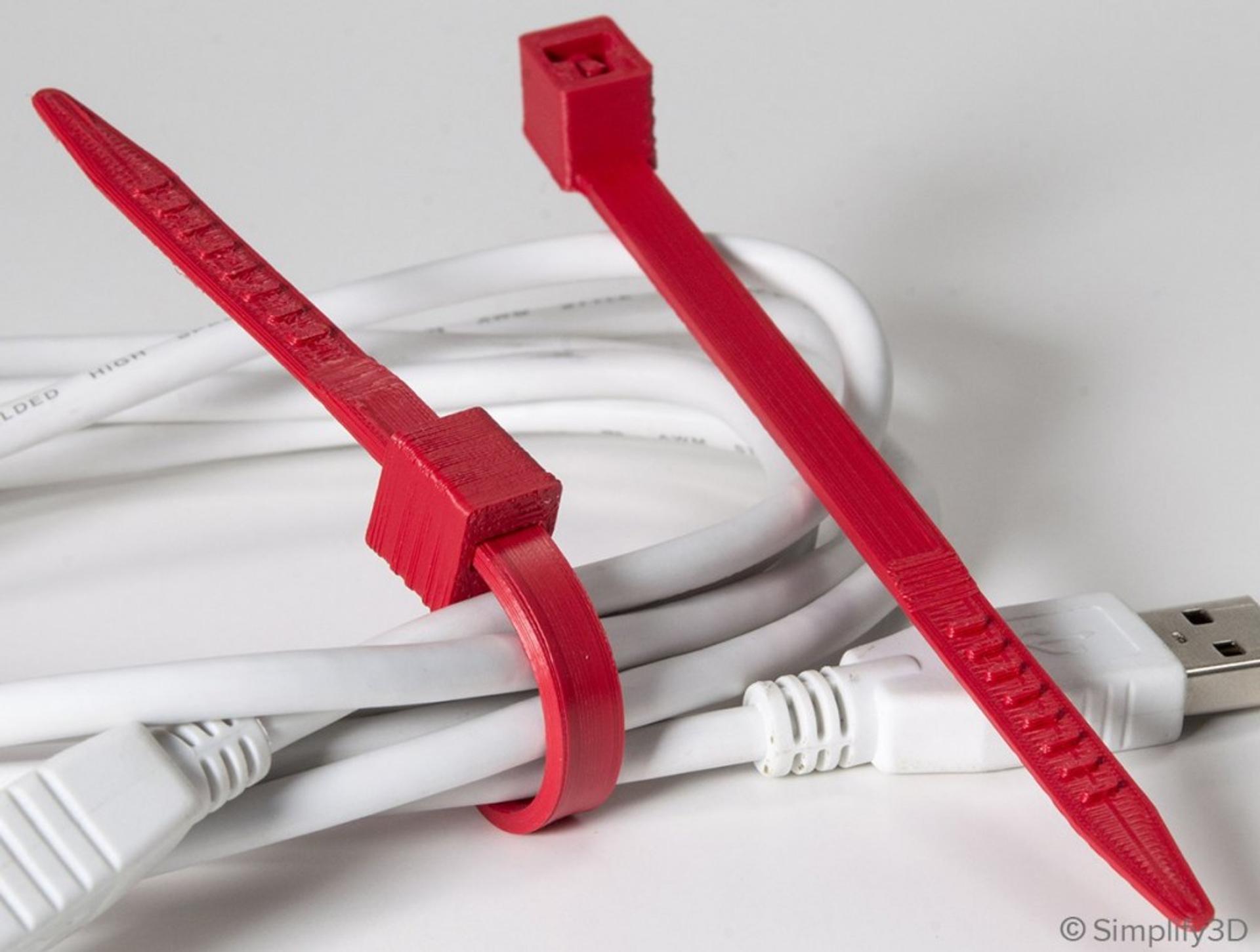

Real-World Part Examples

PLA

Architectural models, cosplay props, decorative prototypes, classroom tools.

PETG

Bottle prototypes, retail enclosures, brackets, safety shields.

ABS

Dashboard mounts, robotics housings, drone shells, working hinges.

Nylon

Custom gears, snap-fit parts, heavy-duty tooling, industrial jigs.

Business Benefits

Accelerated Sales Cycle

Clients feel confident approving quotes quickly.

Reduced Support Time

Fewer back-and-forth emails about “what material to use.”

Increased Trust

Position your team as expert consultants, not just part suppliers.

Higher Retention

Educated clients are more likely to return and request similar materials.

Use Case: Helping a First-Time Buyer Choose

A startup reaches out to print their first prototype. They aren’t sure whether PLA or ABS is better. Your sales rep logs the inquiry in Fabrex CRM and attaches a side-by-side material comparison with their quote. The client selects PETG after reading your recommendation and places the order the same day.

Frequently Asked Questions (FAQ)

PETG and Nylon are more UV- and weather-resistant than PLA or ABS. Nylon is best for mechanical outdoor use; PETG is ideal for containers or enclosures.

PETG is generally considered food-safe if printed on a clean, food-safe printer. However, verify supplier specifications for certification.

PLA is the easiest to print with and most forgiving. It’s great for visual prototypes and non-functional parts.

Yes! While this article focuses on common rigid materials, Fabrex also supports quoting for TPU and other flexible filaments.