MES-Driven Inventory Management for Additive Manufacturing

In additive manufacturing, your materials are as critical as your machines. Managing them effectively means the difference between smooth operations and costly downtime. Yet too often, AM businesses rely on spreadsheets or rigid ERP systems to track high-value powders, filaments, and resins. Fabrex MES changes the game. It brings material visibility and control directly into your production flow—where it belongs.

Why Inventory Management is So Complex in AM

- Materials vary in shelf life, format, and usage.

- Part-specific material assignments require traceability.

- Small disruptions (like running out of a filament variant) halt the entire job queue.

- Volume forecasting is tied to variable print yields.

This complexity makes real-time tracking and traceability essential—and that’s where Fabrex MES shines.

What Makes MES Ideal for Inventory Management?

Live Material Tracking

Stock levels are updated automatically as jobs consume materials.

Job-Linked Usage

Every print job logs what it used, how much, and where it came from.

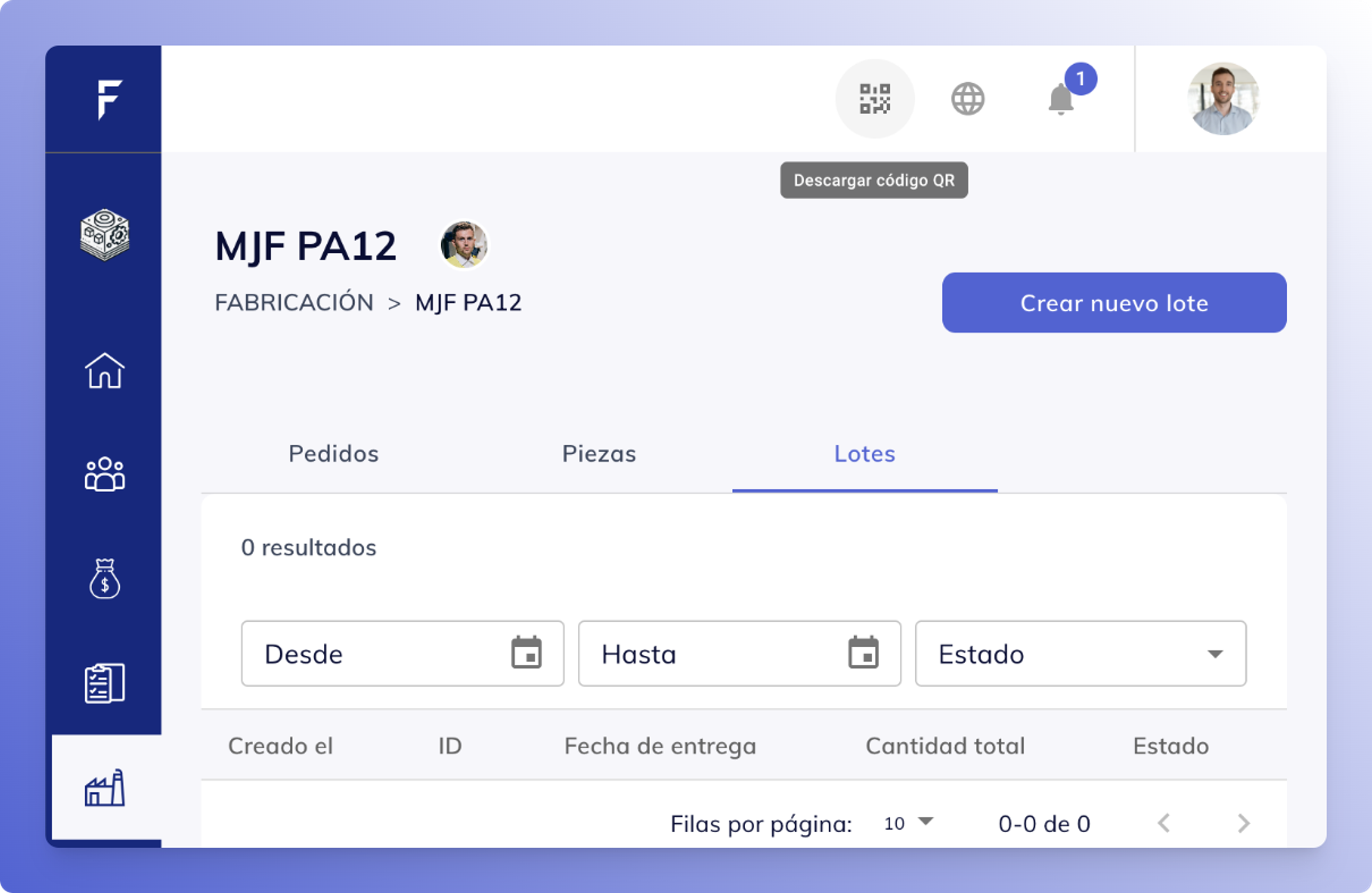

Batch-Level Traceability

Know exactly which material lot was used for which part.

Cross-Machine Sync

Track inventory across multiple printers, stations, or facilities.

Key Features in Fabrex MES

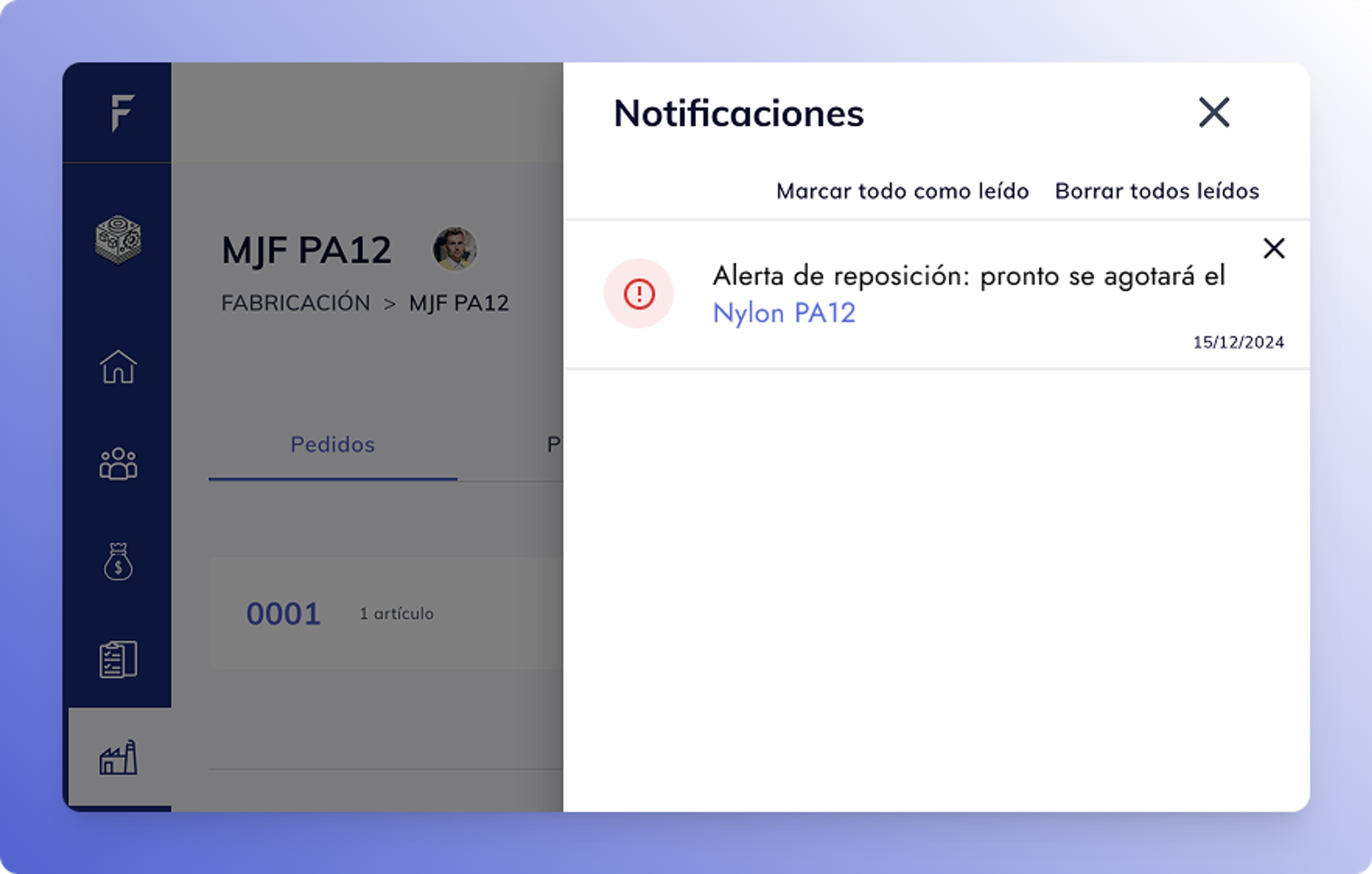

Smart Reorder Points & Alerts

Set thresholds to get notified before you run out of critical stock.

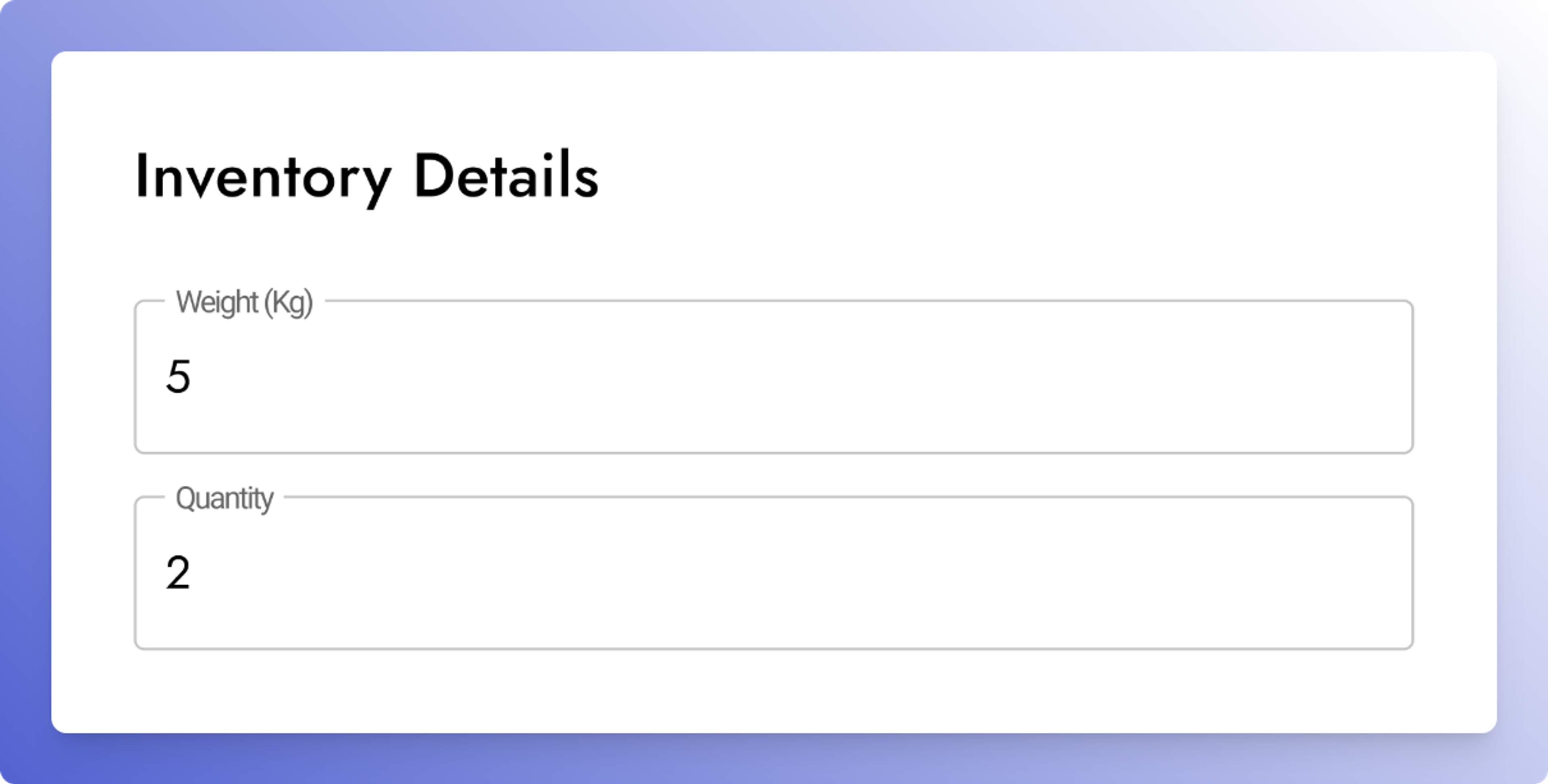

Material-to-Job Linking

Every print job in Fabrex logs its material input by weight or volume.

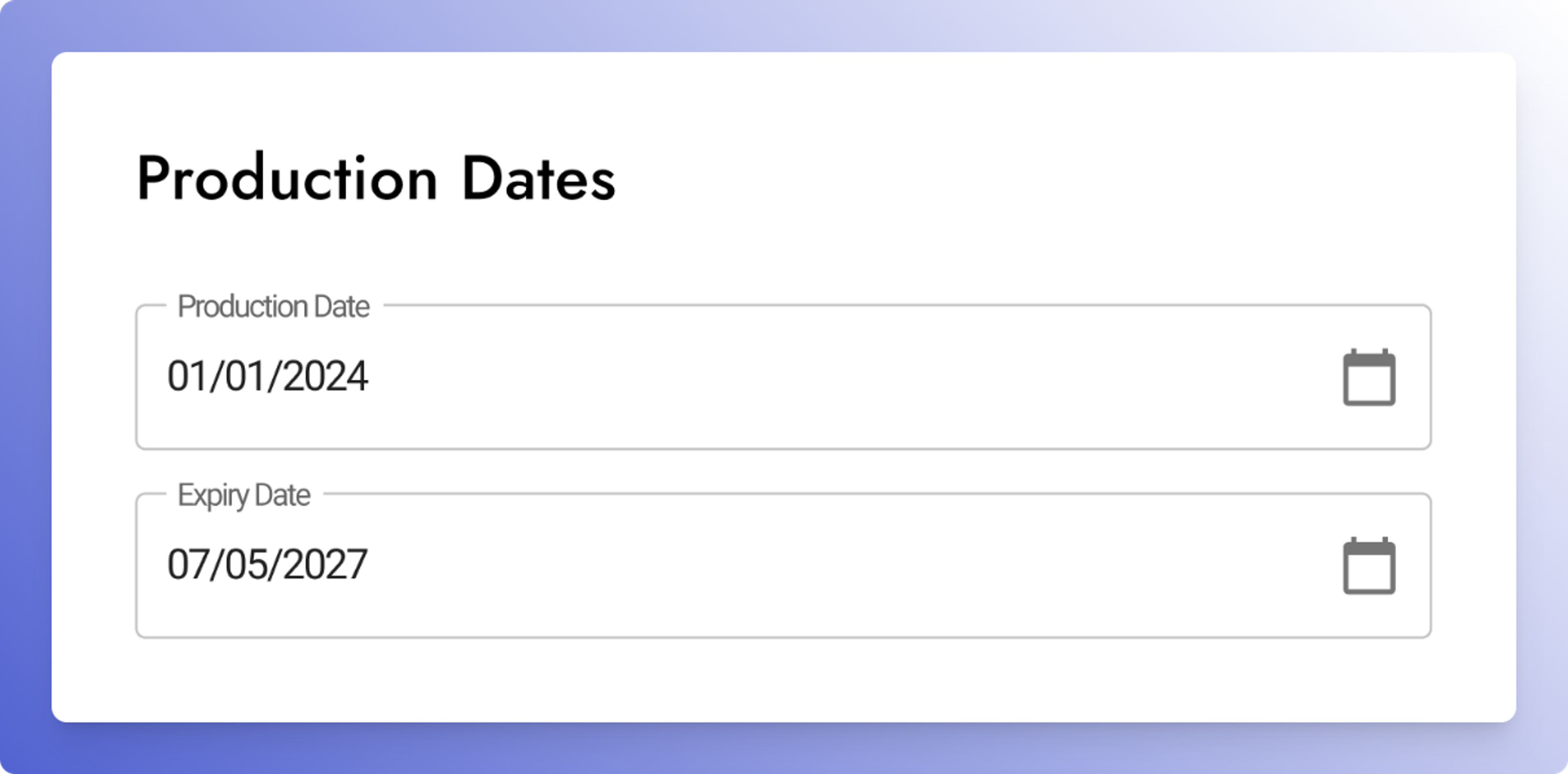

Shelf Life and Expiration Tracking

Automatically track resin, powder, or filament expiry to avoid failed prints or safety issues.

QR-Linked Part-Material Association

Use QR codes to scan parts and retrieve exact material + batch used.

Business Benefits

Reduced Downtime

No more last-minute runs to source materials.

Improved Purchasing

Buy only what you need, when you need it.

Better Compliance

Maintain accurate records for aerospace, medical, or regulated industries.

Lean Manufacturing Support

Aligns perfectly with JIT and digital lean operations.

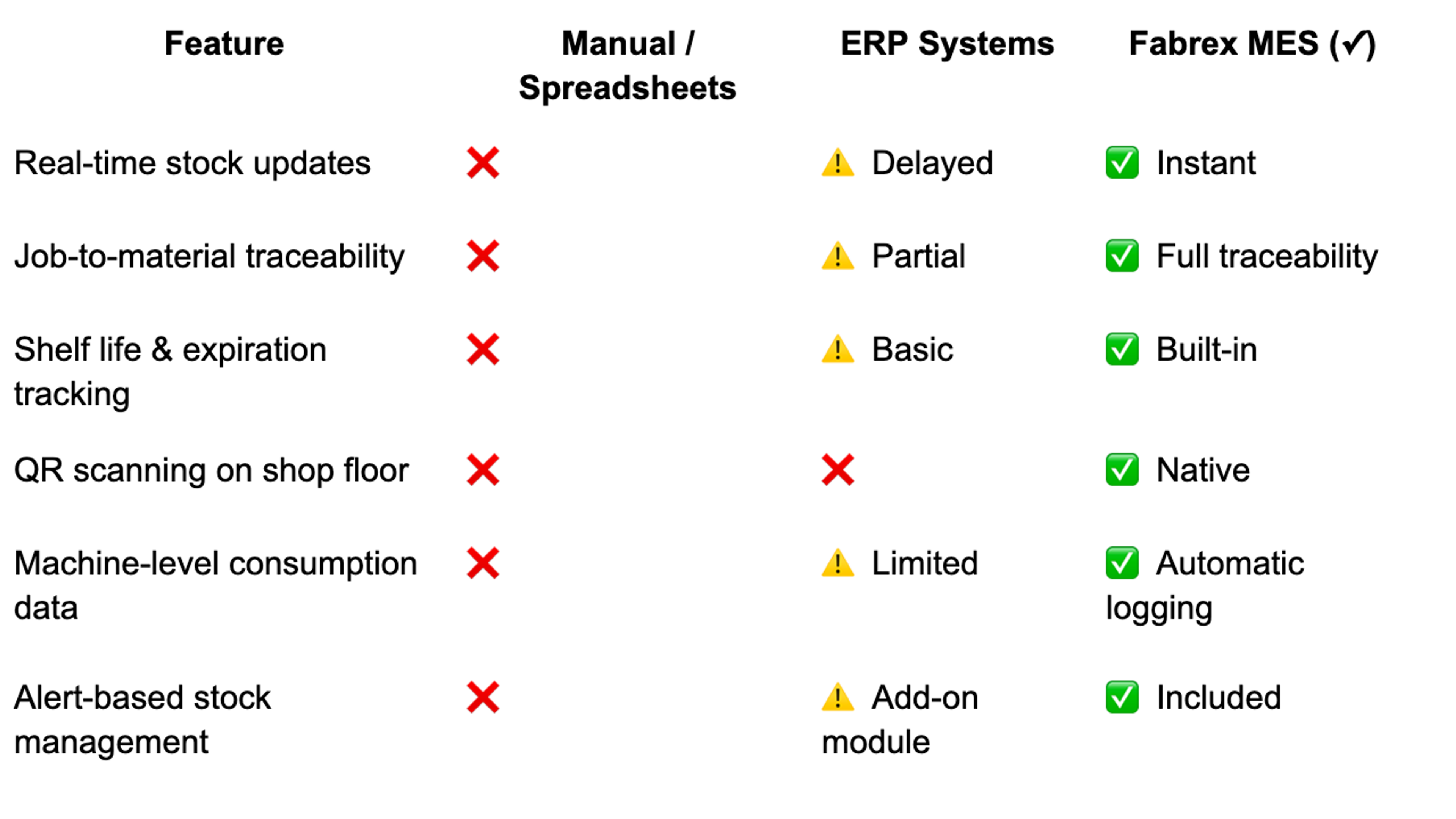

MES vs. Traditional Inventory Systems

Use Case: Daily Inventory Control with Fabrex MES

Imagine starting your day with a Fabrex dashboard showing:

- Today’s jobs and required material loads

- Remaining stock levels by spool, container, or bin

- Expiry warnings for a batch of nylon PA12

- QR scan logs confirming material consumption per printer

Purchasing gets an automated reorder email. Production is informed. And leadership has a full report of what’s been used and what’s needed—without chasing spreadsheets.