Simplify Your 3D Printing Workflow with Fabrex MES

Managing a 3D printing operation can be challenging with complex order tracking, material management, and tight production schedules. Fabrex MES simplifies these challenges, offering intuitive solutions to streamline your entire manufacturing workflow.

Key Features of Fabrex MES

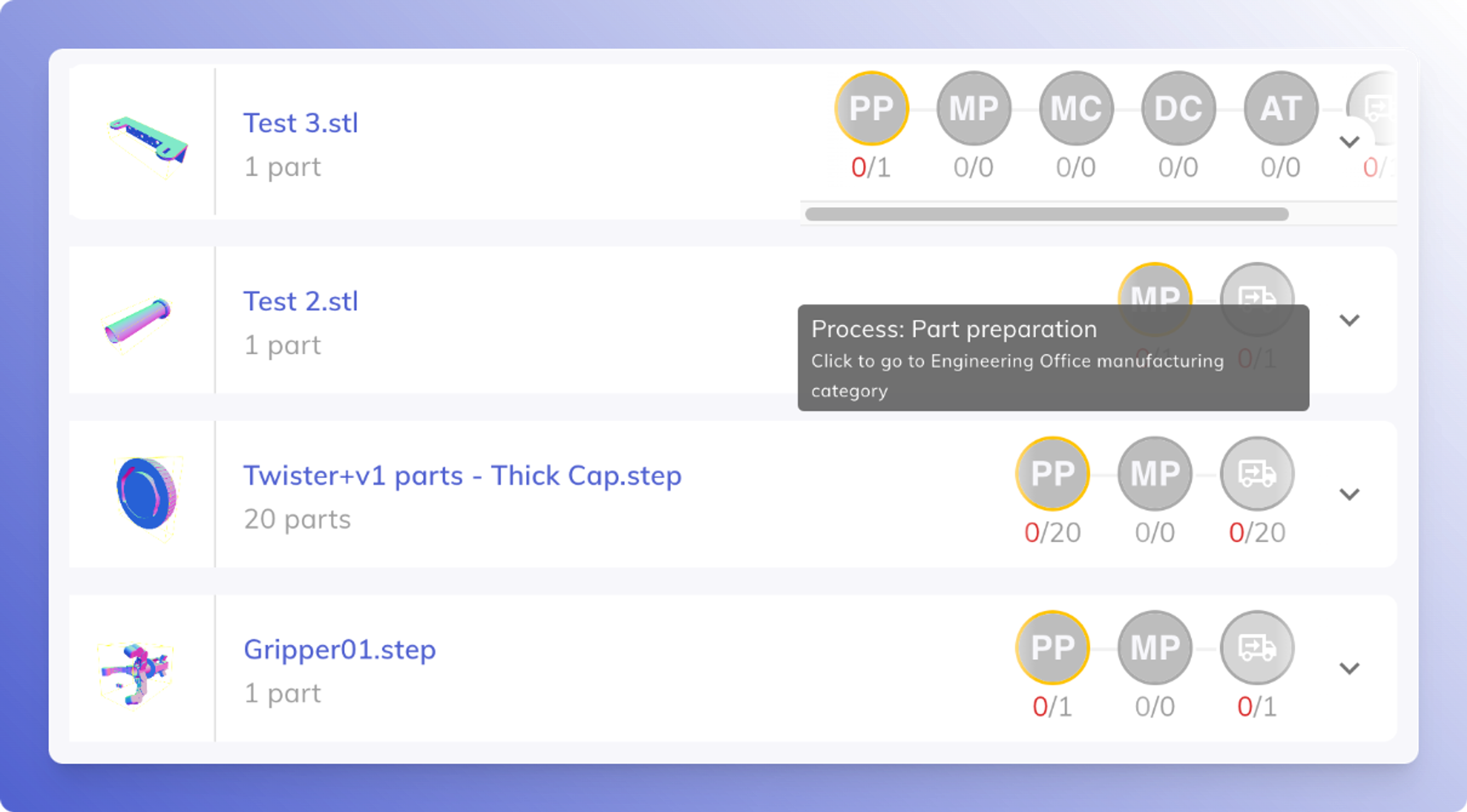

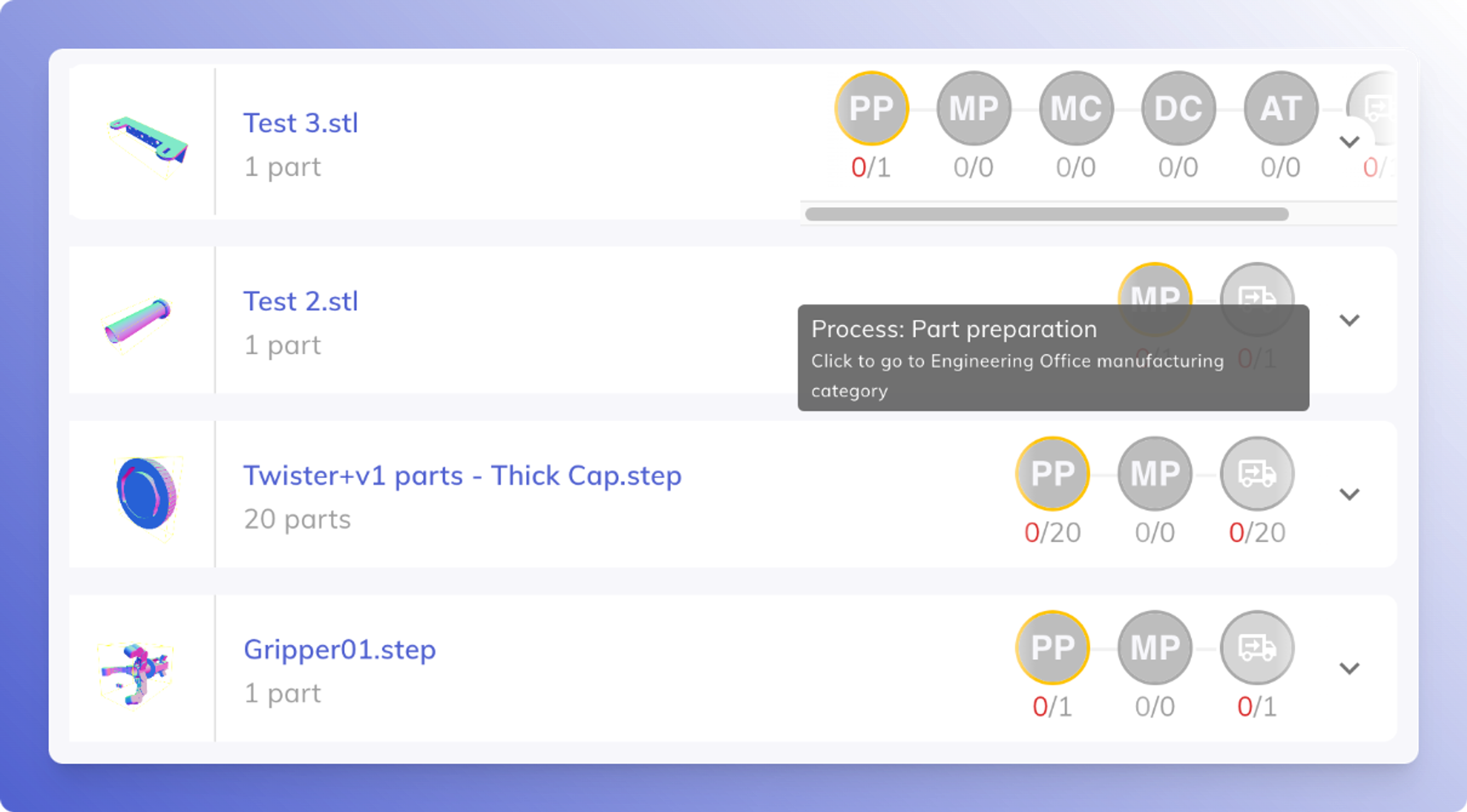

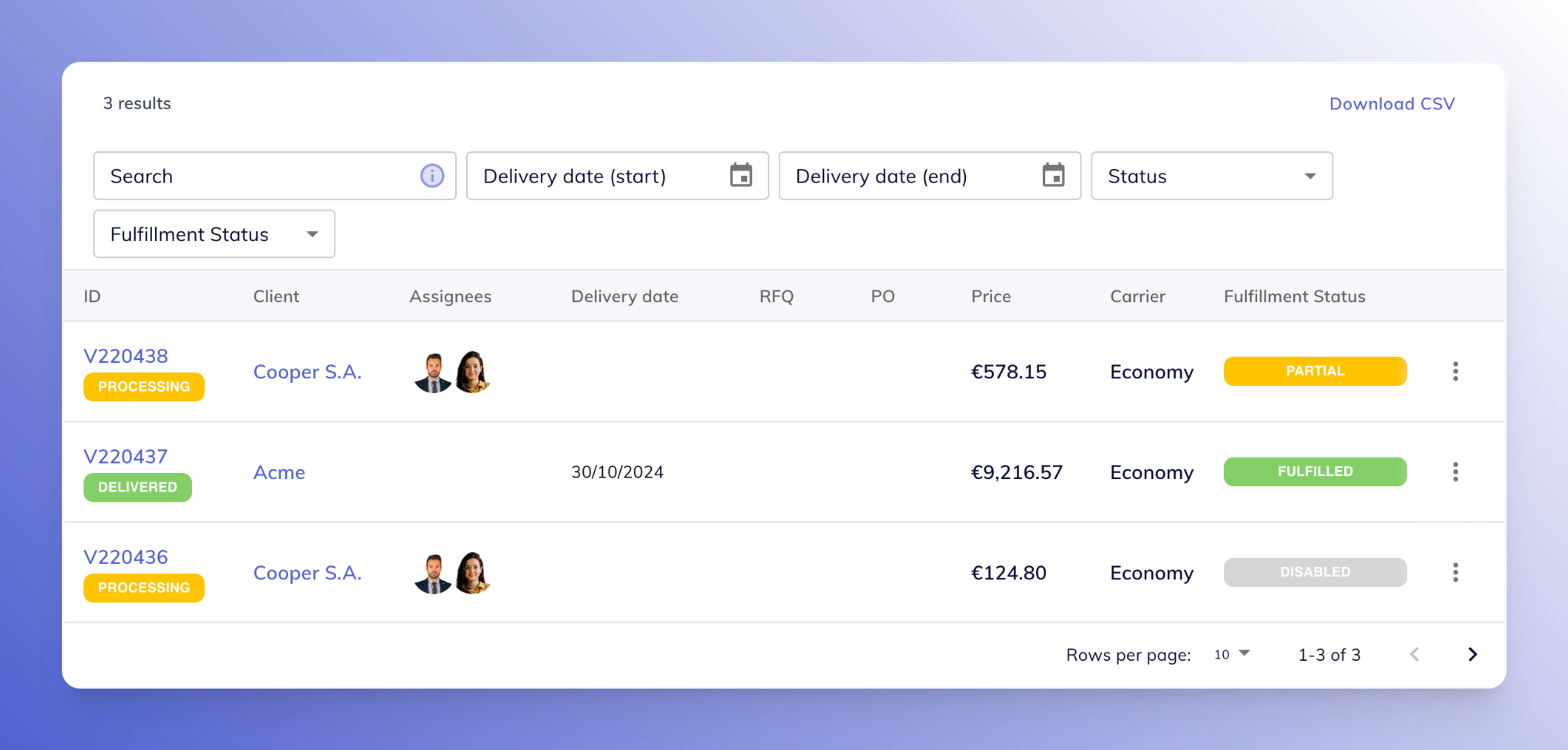

Order Management Automation

Automate your order processes to eliminate manual data entry, reduce errors, and accelerate order fulfillment.

Real-time Workflow Visibility

Keep track of every order in real-time, enhancing your ability to manage production efficiently and meet deadlines consistently.

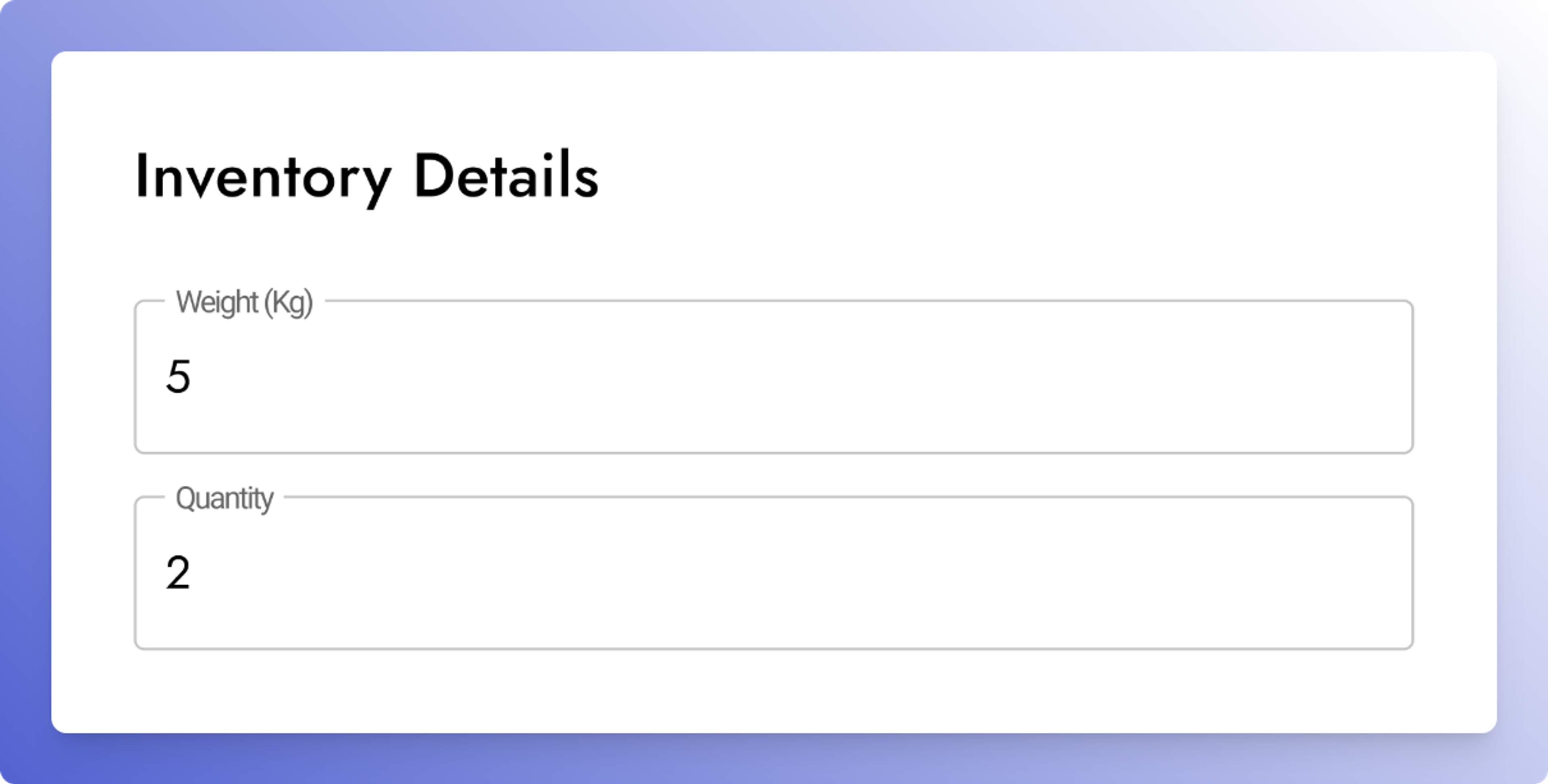

Inventory Tracking and Material Management

Optimize your materials and resources with precise inventory tracking to prevent shortages or excess waste.

Seamless Integration with CRM

Integrate MES and CRM for a complete overview of customer interactions and order statuses, facilitating better communication and service.

Benefits of Using Fabrex MES

Boost Productivity

Automating workflow processes ensures your team can focus on value-added tasks, significantly boosting overall productivity.

Enhance Accuracy

Reduce human errors through automated order tracking and management, leading to increased order accuracy and customer satisfaction.

Improve Scheduling

Real-time insights allow precise scheduling, improving your operational efficiency and capacity planning.

Lower Costs

Efficient resource management and reduced downtime translate directly into cost savings.

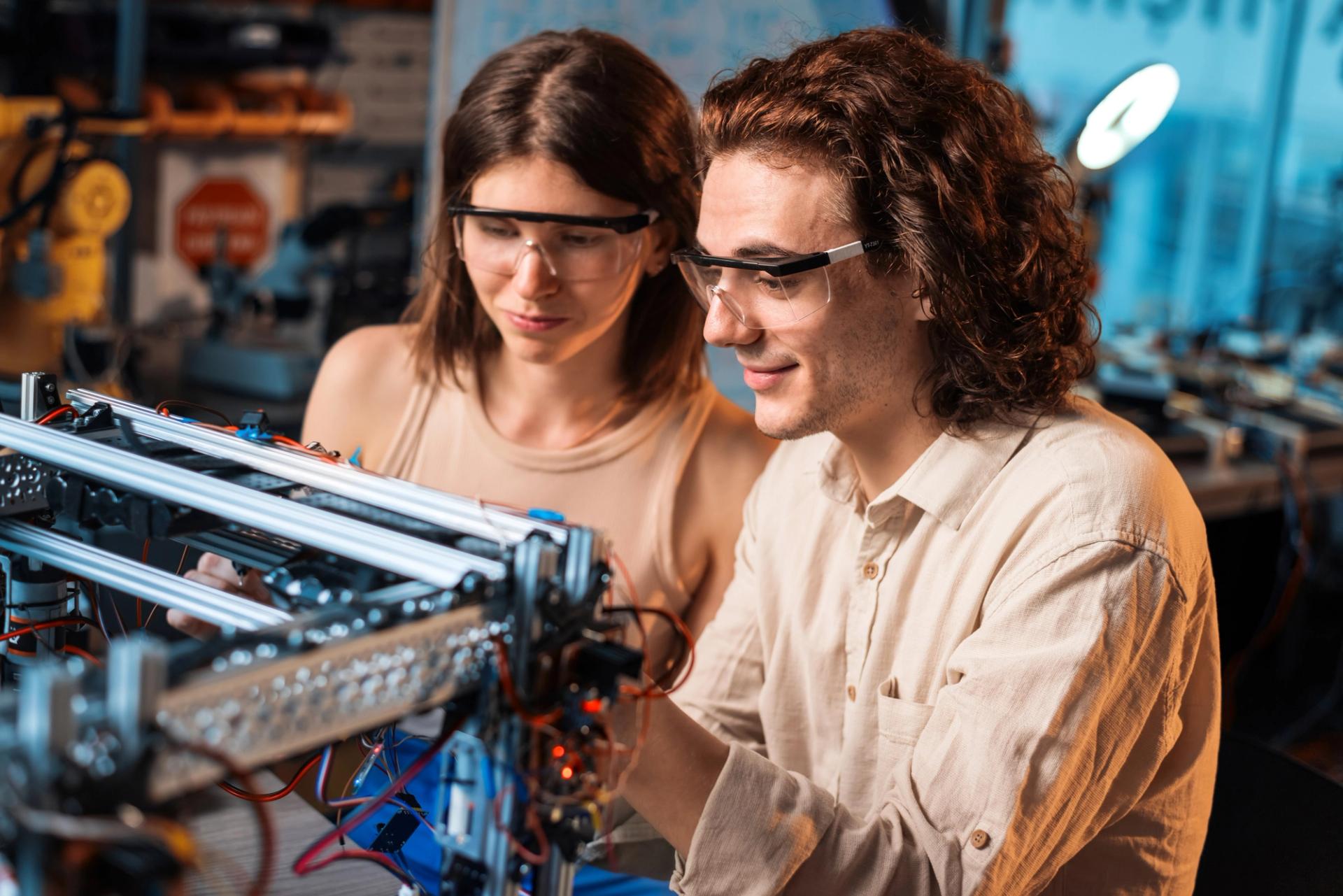

Who Should Use Fabrex MES?

Fabrex MES is ideal for:

High-capacity 3D print farms

Custom manufacturing services

Rapid prototyping firms

Businesses that manage complex, high-volume additive manufacturing workflows

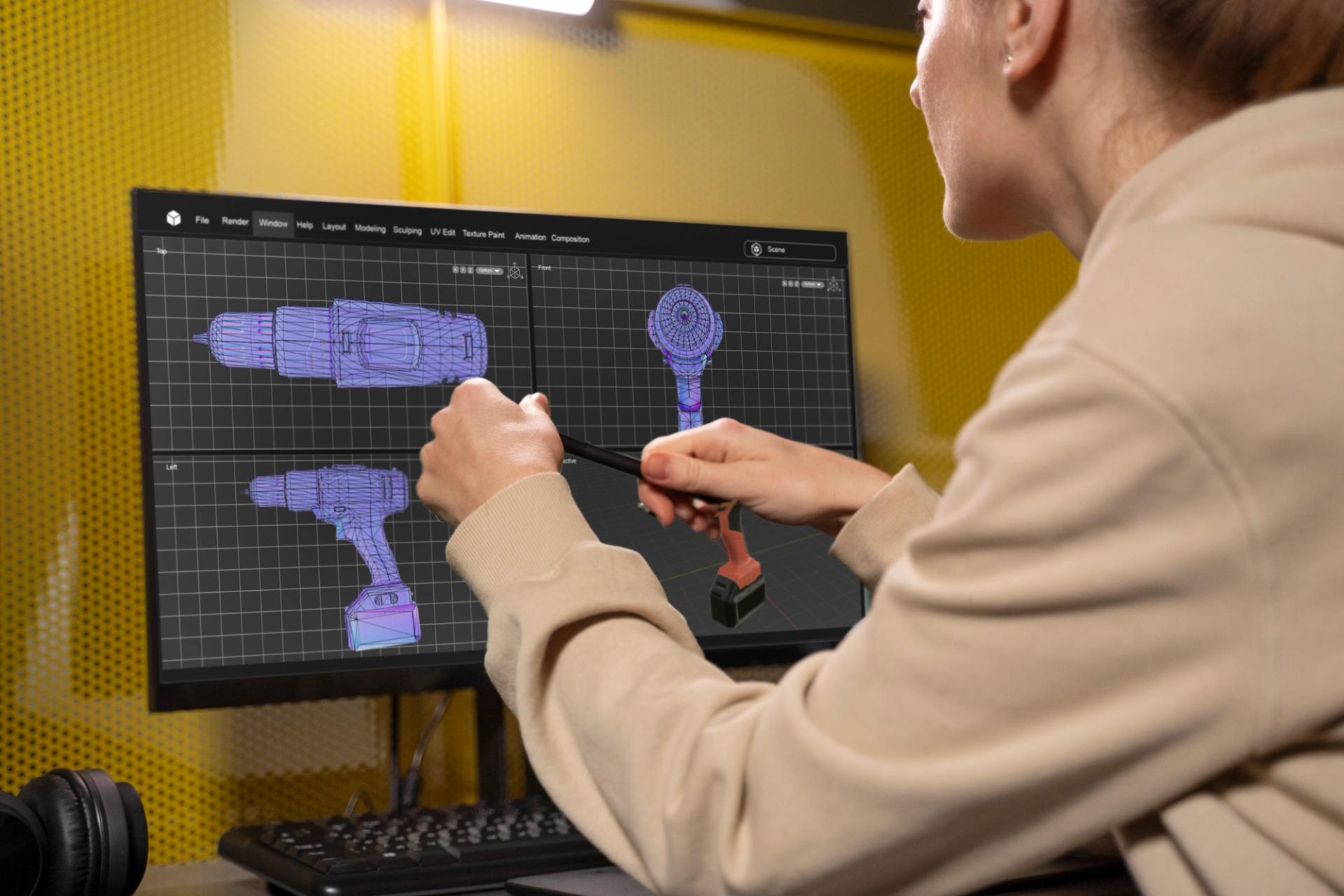

How Fabrex MES Works

Customer Testimonials

Ready to Transform Your 3D Printing Workflow?

Discover firsthand how Fabrex MES can enhance your business operations. Schedule your personalized demo or start your free trial today.