Streamline Your Workflow - Fabrex

Streamline Your Workflow with Fabrex and HP

At Fabrex, we’re bringing simplicity and efficiency to manufacturing with our seamless integration with HP’s MJF and Metal Jet 3D printers. Our platform is designed to manage every step of the production process—from quoting to nesting to production—on a single, intuitive interface.

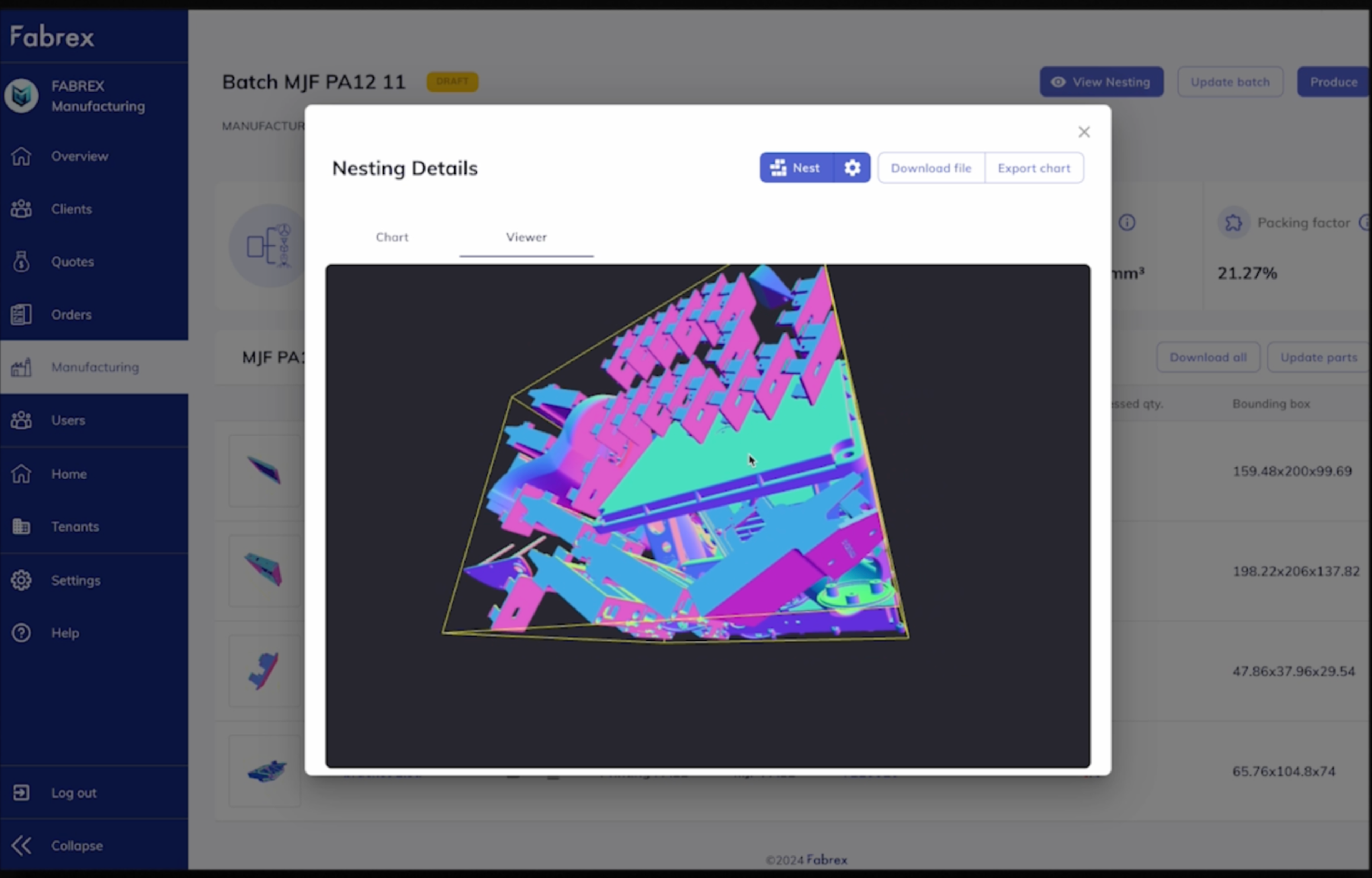

Integrated Nesting: Transforming Build Preparation

Fabrex’s advanced nesting functionality revolutionizes the way manufacturers prepare for production. By automating the build preparation process, our platform not only saves time but also optimizes resource allocation.

By integrating nesting with quoting and production management, Fabrex ensures that every step of the workflow is synchronized, reducing manual intervention and potential errors.

Smart Algorithms for Part Arrangement

Automatically nest parts to maximize material usage and minimize waste

Seamless Build Preparation

Generate printer-ready files directly within Fabrex

Batch Management

Consolidate multiple orders into a single, optimized production batch

Dynamic Updates

Automatically adjust nesting configurations for last-minute changes in order quantities or priorities

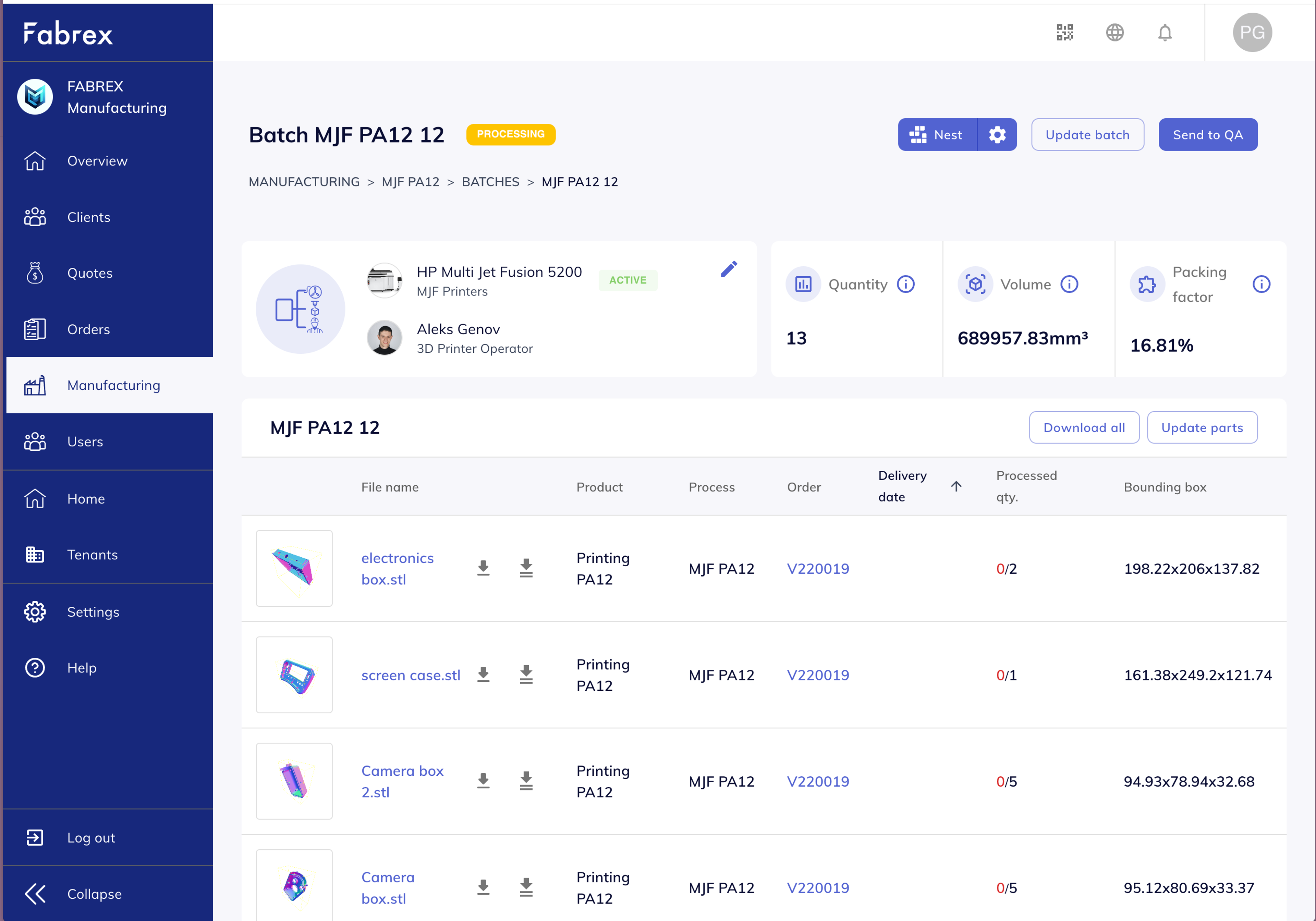

Streamlined Production Management with Fabrex and HP

Fabrex and HP bring you a seamless, efficient, and data-driven manufacturing workflow, integrating directly with HP’s MJF and Metal Jet 3D printers to optimize every stage of production.

Direct Job Sending

- One-Click Job Transfer: Send builds directly from Fabrex to HP printers without manual file uploads.

- Optimized Build Preparation: Ensure builds are prepared in formats tailored for HP’s advanced 3D printing capabilities, delivering top-quality results.

Real-Time Machine Monitoring

- Live Status Updates: Track job progress, monitor machine availability, and anticipate completion times.

- Proactive Error Management: Receive instant alerts for machine issues, enabling quick resolutions to minimize downtime.

Logs and Metrics for Productivity Gains

- Detailed Machine Logs: Access comprehensive reports on machine activity, including print times, material usage, and downtime events.

- Data-Driven Optimization: Use real-time metrics to refine workflows, improve scheduling, and maximize printer utilization.

From Quoting to Nesting to Production

With Fabrex, you can manage the entire manufacturing workflow on one platform:

1. Accurate Quoting:

- Generate instant, precise quotes tailored to your processes and materials.

- Customize pricing with our smart formula system to reflect the unique complexity of each product.

2. Streamlined Nesting:

- Automate build preparation and send jobs directly to your HP printer.

- Optimize layouts for efficiency and cost-effectiveness.

3. Production Management:

- Track job progress in real-time with end-to-end visibility.

- Transition seamlessly from build preparation to production execution.

The Benefits of Automated Build Preparation

By automating the build preparation process with Fabrex, manufacturers can unlock:

- Significant Time Savings: Reduce hours spent on manual nesting and file preparation.

- Increased Productivity: Free up resources to focus on high-value tasks.

- Optimized Resource Utilization: Ensure every material is used efficiently with smart part arrangement.

- Improved Accuracy: Minimize errors in file preparation and nesting, leading to higher-quality outputs.

Fabrex for HP Integration?

Fabrex doesn’t just connect to your HP printers—it enhances every aspect of your workflow:

End-to-End Integration

From quoting to delivery, Fabrex ensures every process is connected.

User-Friendly Interface

Simplify complex tasks with an intuitive platform that’s easy for your team to adopt.

Real-Time Insights

Stay informed with live updates on job progress, material usage, and production performance.

Future-Ready Solution

As your business grows, Fabrex scales with you, adapting to new technologies and workflows.